Drying of Bricks

Drying of Bricks

Before burning it is essential that the bricks have dried and have become sufficiently hard to be handled and stacked in kilns without getting damaged. Also if the bricks have not completely dried then they are likely to get cracked and distorted when burnt in the kiln.

The following points are kept in view to ensure successful completion of drying operation.

i. As soon as the moulded bricks become dry enough so that they do not get damaged on handling they should be turned on edge and left for a day or two more t o further harden. In the initial stage of drying, bricks should be protected from sever sun and winds as otherwise rapid drying of bricks might result in their developing cracks.

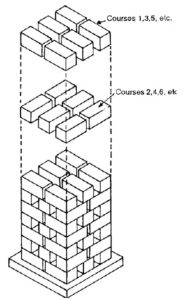

ii. They should then be stacked in such a way that each brick gets full circulation of air all Stock Board around it. Best form of stack is of a breadth equal to two bricks laid longitudinally with interval between them. The alternate layers being along and across the stack and all placedon edges.

iii. The drying area should be higher than the surroundings so that it does not get flooded due to any occasional rain. It should have a gentle slope to facilitate drainage of rain water.

iv. A layer of sand should be spread at the drying area so as to keep it dry in wet weather.

v. To protect the drying, bricks from damage caused by occasional rains temporary bamboo frames and sirki should be provided. The sirkis should be weighed down with heavy planks to stop them from being blown away by winds. The height of stack may be of eight to ten layers of bricks.

A gap of about 1 m should be left between adjacent stacks so as to facilitate free movement of workers.

Length and height of all the stacks should be kept the same. Every stack should contain bricks in multiples of a thousand. This shall make it easy to count the number of bricks. Depending upon weather it takes three to eight days for bricks thoroughly dry.

1. Manufacturing of Bricks

2. Moulding of Bricks

3. Drying of Bricks

4. Burning of Bricks

5. Hoffmann’s kiln and Bull’s trench kiln

Drying of Bricks, Drying of Bricks, Drying of Bricks, Drying of Bricks, Drying of Bricks, Drying of Bricks