Properties of Stone Aggregates

Sand, gravel and crushed stone fall into this category and make up a large percentage of the aggregates used in concrete. Since they generally constitute from 60 to 80 percent of the volume of concrete, their characteristics influence the properties of concrete. They should therefore meet certain requirements if the concrete is to be strong, durable, and economical. They must be of the proper shape, either rounded or approximately cubical in shape, clean, hard, strong, and well graded. They must possess chemical stability and in many cases exhibit abrasion resistance and resistance to freezing and thawing.

1. SHAPE AND SURFACE TEXTURE

The particle shape and the surface texture of aggregates influence the properties of fresh concrete more than those of hardened concrete. Sharp, angular, and rough aggregate particles require more paste to make good concrete than do rounded ones. Flat, Slivery pieces make concrete more difficult to finish and should be limited to not more than 15 percent of the total. This requirement is particularly important for crushed fine aggregate, since materials made in this way contains more flat and elongated particles.

2. CLEANLINESS OF AGGREGATES

Particles should be free from coatings of clay or other fine material and from organic impurities which may affect the setting of the cement paste. In the case of coarse aggregates, visual inspection will often disclose the presence of such deleterious materials, but where doubt exists, the aggregates should be tested. However, it is not so easy to inspect fine aggregate in the same way, and standard tests may be carried out to determine the amount of silt and organic materials present in the aggregates.

3. AGGREGATE GRADING

Grading, or particle size distribution, is an important feature of aggregates and is determined by a sieve analysis, as specified by ASTM C136. The sieves used included the following sizes: Nos. 4, 8,16, 30, 50, and 100 for fine aggregate and 6 in, 3 in, 1½ in, ¾ in, 3/8 in, and No. 4 for coarse aggregate. Limits are usually specified for the percentage of material passing each sieve, Grading limits and maximum size of aggregates are important because they affect relative aggregate proportions, cement and water requirements, workability, economy, porosity, shrinkage, and durability of

concrete. In general, aggregates which conform to the grading limits produce the most satisfactory results.

4. MOISTURE CONTENT OF AGGREGATES

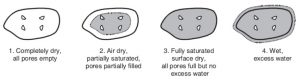

Two types of moisture are recognized in aggregates: absorbed moisture and surface moisture. Absorbed moisture is that which is taken in by the voids in aggregate particles and may not be apparent on the surface, while surface moisture is that which clings to the surface of the particle. The absorbed and surface moisture of aggregates need to be determined in order to control the net water content of a concrete mix and to make adjustments in batch weights of the materials. The

moisture conditions of aggregates are designated as follows:

Oven-Dry: In this condition they are fully absorbent.

Air-Dry: Particles are dry at the surface but contain some interior moisture. They are therefore somewhat absorbent.

Saturated Surface-Dry: In this condition there is no water on the surface, but the particle contains all the interior moisture it will hold. It will neither absorb moisture from nor contribute moisture to the mix.

Damp or Wet: The particles contain an excess of moisture on the surface and will contribute moisture to mix.

5. SPECIFIC GRAVITY

The specific gravity of an aggregate is another characteristic of the material which needs to be determined. It is not a measure of aggregate quality but is used in making calculations related to mix design. The specific gravity of most normal weight aggregates will range from 2.4 to 2.9. Test methods for determining specific gravity of both coarse and fine aggregates are described in ASTM C127 and C128.

6. HARDNESS OF AGGREGATES

The hardness of aggregates is expressed in terms of their resistance to abrasion. The characteristic is important if the aggregate is used in concrete intended for such purposes as heavy-duty floors. A common method of making this test is described in ASTM C131 or C535 and consists of placing a specified quantity of the aggregate to be tested in revolving steel drum.

7. STRENGTH OF AGGREGATES

One measure of the strength of an aggregate is its resistance to freeze-thaw. This resistance is an important characteristic in concrete which is exposed to severe weather. The freeze-thaw resistance of an aggregate is related to its porosity, absorption, and pore structure. If a particle of the aggregate absorbs so much water that there is not enough pore space available, it will not accommodate the expansion which takes place when the water freezes and the particle will fail. Freeze-thaw tests on aggregates are commonly carried out on specimens of concrete made with the aggregate.

8. CHEMICAL STABILITY OF AGGREGATES

Aggregates need to be chemically stable so that they will neither react chemically with cement nor be affected chemically by outside influences. In some cases aggregates with certain chemical constituents react with alkalis in cement. This reaction may cause abnormal expansion and resultant cracking of concrete. There are three tests used for testing aggregates for reactivity to alkali: ASTM C227, ASTM C289, and ASTM C586.

Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates Properties of Stone Aggregates, Properties of Stone Aggregates, Properties of Stone Aggregates Properties of Stone Aggregates

how aggregate angularity impacts rutting in asphalt layer?