What is Concrete

What is Concrete ?

Concrete is the mixture of cement, coarse aggregate, fine aggregate and water in specific proportions. Concrete is relatively a brittle material —– its tensile strength is very small as compared with its compressive strength. This disadvantage can be offset by reinforcing or pre-stressing concrete with steel reinforcement. Reinforced concrete (RC) possesses many of the best properties and is used in variety of construction including building frames, floors, slabs, walls; bridges; pavements; piles; dams; water retaining structures etc.

VARIOUS TERMS USED / STEPS FOR CONCRETING OPERATION

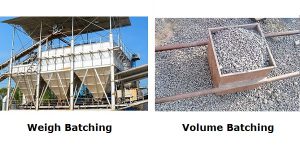

a) Batching

The process of proper and accurate measurement of concrete ingredients to ensure uniformity of proportions and aggregate grading as per mix design proportions is called batching. Batching may be by volume or by weight.

Batching by Volume

Batching by volume is generally adopted for general construction works and it is carried out by using wooden or steel boxes, wheel barrows, etc. In volume batching, bulking effect of sand has to be taken into account.

Batching by Weight

Batching by weight is adopted for large and important projects and batching plants are used for this purpose. Weight batching is more accurate than volume batching.

b) Mixing

After correct batching all the ingredients of concrete are thoroughly mixed until the concrete of uniform color and required consistency is obtained. Mixing of concrete may be done manually or mechanically.

Manual Mixing

Manual mixing is adopted for small and unimportant construction activities. Concrete is less efficient and requires more cement than that required in machine mixing to obtain the same strength.

Machine Mixing

Machine Mixing

Machine mixing is adopted for general construction works and in this batch mixers or continuous mixers are used. Batch mixers are either with tilting drum or with non-tilting drum. Batch mixers are available in various capacities. Batch mixers with tilting drum are most commonly used. For general works 10/7 or ¼ cubic yard capacity mixers are used. 10/7 means 10 cubic feet of dry material yields 7 cubic feet of wet concrete. 1-cement bag capacity mixers are convenient and generally used. Mixing time shall not be less than 90 seconds.

Ready-mixed concrete is batched in central batching plants and delivered to various job-sites in trucks, usually mixer mounted. The concrete may be mixed en route or after arrival at the site. Concrete may be kept plastic and workable for as long as 1.5 hours by slowly revolving the mixer. However, better control of mixing time can be maintained if water is added and mixing started after arrival of the truck at the job, site where the operation can be inspected.

Ready-mixed concrete is batched in central batching plants and delivered to various job-sites in trucks, usually mixer mounted. The concrete may be mixed en route or after arrival at the site. Concrete may be kept plastic and workable for as long as 1.5 hours by slowly revolving the mixer. However, better control of mixing time can be maintained if water is added and mixing started after arrival of the truck at the job, site where the operation can be inspected.

c) Transportation

The process of carrying the concrete from the place of mixing to the place of final position of its deposition is known as transportation. Transportation may be manual or mechanical.

Manual Transportation

Manual transportation is adopted for small construction activities and when the place of deposition is closed to the place of mixing.

Mechanical Transportation

Mechanical Transportation

Mechanical transportation through pumps or lifts’ and is adopted for large construction activities or when the place of deposition is away from the place of mixing. Minimum time should be consumed in transportation. Horizontal & Vertical transportation.

d) Placing of Concrete

The process of depositing the concrete in its required position is called placing of concrete. Concrete should be placed carefully in position and should not be thrown from heights to avoid segregation. When working is to be suspended / stopped for some time, grooves should be made in the finish work for joining the next concrete work before its initial setting.

e) Compaction and Finishing

The process of consolidating the concrete after placing in its position is known as compaction of concrete. With the presence of air bubbles / voids in the concrete, its strength reduces considerately. 5% air voids in concrete may reduce its strength up to 30%. Compaction may be manual or by mechanical means.

Manual Compaction

Manual compaction through tempering and rodding is adopted for small and less important concrete works.

Mechanical Compaction

Mechanical compaction through vibrators is done for large, massive and general concrete works. Vibrators may be external or internal types.

f) Curing of Concrete (Click here to read about curing of concrete)

What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete, What is Concrete