Experiment No. 4:

Determination of the aggregate impact value of different coarse aggregate samples. (BS 812)

Scope & significance: Aggregate Impact Value

The aggregate impact value gives a relative measure of the toughness or the resistance of aggregate sudden shock or impact is not proportional to the resistance to a slowly applied compressive load. Aggregate Impact Value

Related Theory:

Aggregate Impact Value:

- AIV is the percentage of fines produced from the aggregate sample after subjecting it to a standard amount of impact. Aggregate Impact Value

- The standard amount of impact is produced by a known weight, i.e. a steel cylinder, falling a set height, a prescribed number of times, onto an amount of aggregate of standard size and weight retained in a mould.

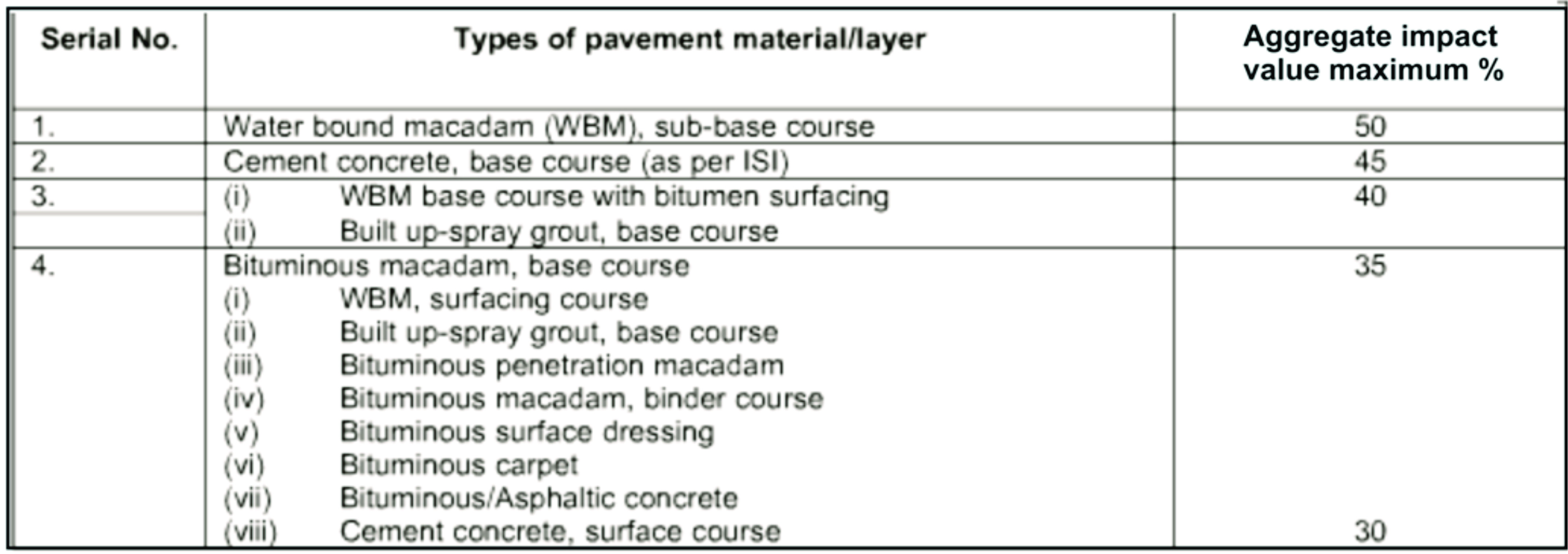

- Aggregate Impact Values, (AIV’s), below 10 are regarded as strong, and AIV’s above 35 would normally be regarded as too weak for use in road surfaces.

- Aggregate Impact Values and Aggregate Crushing Values are often numerically very similar, and indicate similar aggregate strength properties. Aggregate Impact Value

Test Specifications:

Aggregate Impact Value. The test sample shall consist of aggregates the whole of which passes through ½ in B.S. test sieve and is retained on a 3/8 in B.S. test sieve. The aggregate comprising the test sample shall be dried in an oven for a period of four hours at a temperature of 100-110 °C and cooled.The measuring cup shall be filled about one-third with the aggregate and gives 25 no. of blows with tamping rod. A further similar quantity of aggregate shall be added and a further 25 tamping given to the second and tot the last layer 25 tamping shall again be given and the surplus aggregate struck off using the tamping rod as a straight-edge. The net weight of aggregate in the measure shall be determined to the nearest gram (weight A) and this weight shall be used for the duplicate test on the same material. Aggregate Impact Value

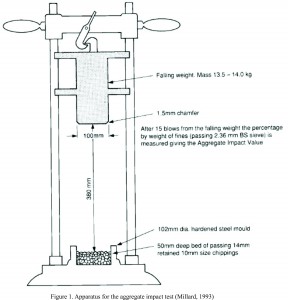

Apparatus: Aggregate Impact Value

- Coarse aggregate from various sources

- Impact testing machine

- Spanner

- Balance

Procedure: Aggregate Impact Value

Aggregate Impact Value. The cup shall be fixed firmly in position on the base of the machine and the whole of the test sample will be placed in it and compacted by a single tamping of 25 strokes of the tamping rod. The hammer shall be raised until its lower face is 15 in. above from the upper surface of the aggregate in the cup, and allowed to fall freely on the aggregate. The test sample shall be subjected to a total 15 such blows each being delivered at an interval of not less than one second. The crushed aggregate shall then be removed from the cup and the whole of it sieved on No. 7 B.S. sieve until no further significant amount passes in one minute. The fraction passing the sieve shall be weighted to an accuracy of 0.1 gram (weight B). Te fraction retained on the sieve shall also be weighed (weight C), and if the total weight B + C is less than the initial weight (weight A) by more than 1 gm the result shall be discarded and a fresh test made. Two tests shall be made. Aggregate Impact Value

Calculations

The ratio of the weight of fines formed to the total sample weight in each test shall be expressed as a percentage, the result being recorded to the first decimal place. Aggregate Impact Value

Aggregate Impact Value = (B/A)*100

where

A = weight of oven dried sample Aggregate Impact Value

B = weight of fraction passing B.S. sieve No. 7

Observations & Results:

A = Total Wt. of the Sample

B = Fraction passing BS sieve #7 after crushing Aggregate Impact Value

Aggregate Impact Value =(B/A)*100

Cup Diameter =……4 inches….. Depth of Cup = ………2.5 inches……..

Weight of Hammer = ……14 lbs……. Drop Height = ………15 inches……..

|

Name of Sample = SARGODHA CRUSH |

|||||

|

Sample No |

Wt of sample A (gm) |

Wt of sample passing BS No. 7 Sieve B (gm) |

Wt of sample retained on BS No. 7 Sieve C (gm) |

Impact Value = ( B/A) x 100 (%) |

Type Of Aggregate |

|

1 |

372 |

25 |

347 |

6.72 |

good |

|

2 |

383 |

31 |

352 |

8.09 |

good |

|

3 |

353 |

25 |

328 |

7.08 |

good |

|

Name of Sample = MARGALA CRUSH |

|||||

|

Sample No |

Wt of sample A (gm) |

Wt of sample passing BS No. 7 Sieve B (gm) |

Wt of sample retained on BS No. 7 Sieve C (gm) |

Impact Value = ( B/A) x 100 (%) |

Type Of Aggregate |

|

1 |

342 |

48 |

294 |

14.04 |

fair |

|

2 |

352 |

46 |

306 |

13.07 |

fair |

|

3 |

341 |

30 |

311 |

8.8 |

good |

|

Name of Sample = MARGALA + SARGODHA CRUSH |

|||||

|

Sample No |

Wt of sample A (gm) |

Wt of sample passing BS No. 7 Sieve B (gm) |

Wt of sample retained on BS No. 7 Sieve C (gm) |

Impact Value = ( B/A) x 100 (%) |

Type Of Aggregate |

|

1 |

354 |

41 |

313 |

11.58 |

fair |

|

2 |

354 |

38 |

316 |

10.73 |

fair |

COMMENTS: Aggregate Impact Value

The aggregate impact value indicates a relative measure of the resistance of the aggregate to a sudden shock or impact which in some aggregates differs from its resistance to a slow compressive load. From the calculations done we came to know that the sargodha crush is a good aggregate and margala crush and the mixture of margala and Sargodha are also close to the maximum allowable limit for good aggregates Hence they can be acceptable as their Aggregate Impact value is less then 35. Aggregate Impact Value

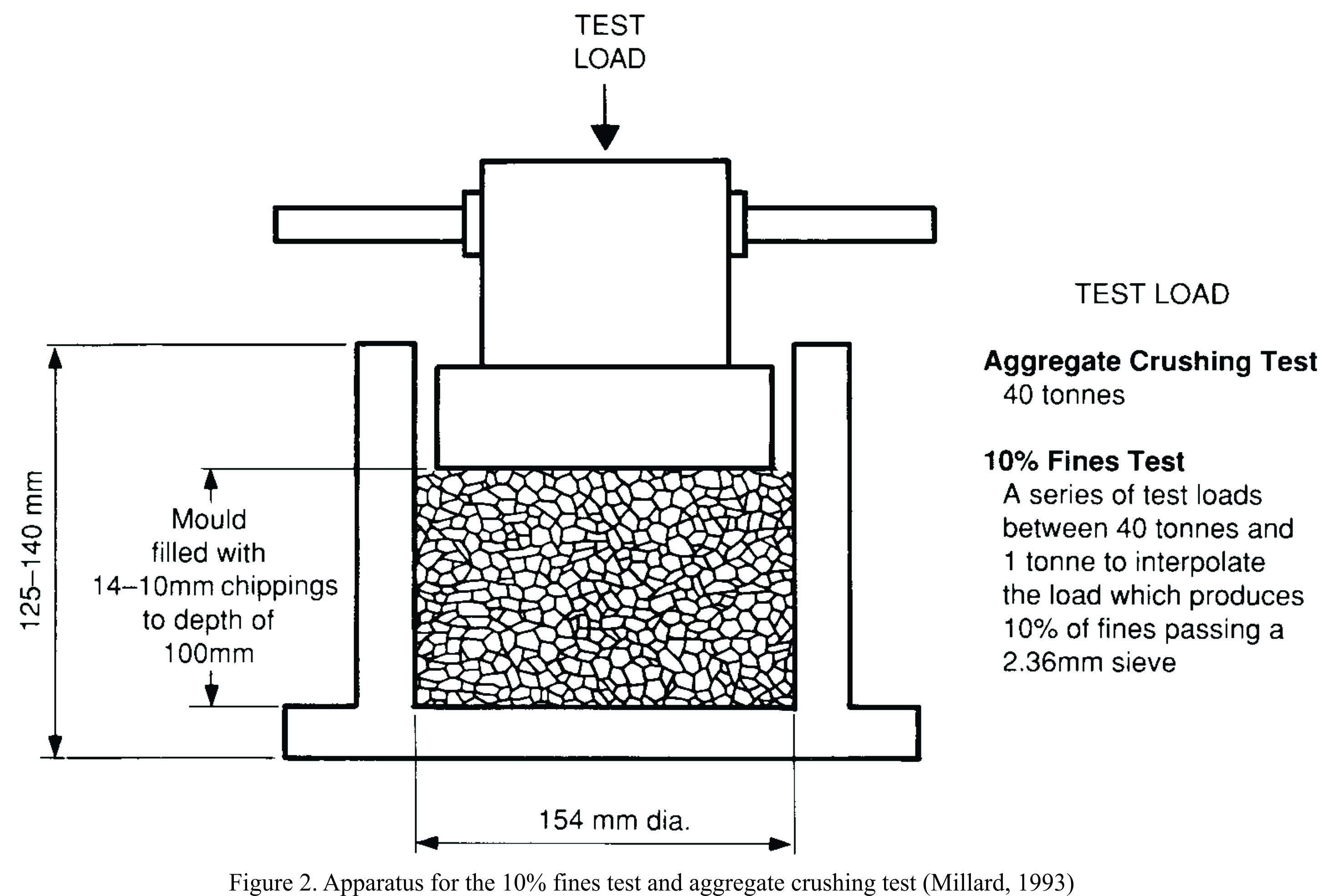

Please I need more explanation about acv,what is the difference between acv and aiv?

please how do I carry out moisture content test on granite (coarse aggregate)

Also how do I perform specific gravity on granite too

Search for these experiments here

nice information

Great Post Sir. Learning Civil Engineering is Fun with you.

Thanks