Experiment No. 10:

Determination of the tensile strength of concrete by Double Punch Test. (Non-Standard Test)

Apparatus:

- Testing Machine

- Testing Samples

- Punches (2 in number, to be placed at the top and bottom of the sample) Double Punch Test

Test Specifications:

Size Of The Specimen

The specimen is a cylinder of 150mm diameter and 150mm height.

Procedure:

It is an indirect method in which we determine the tensile strength of concrete based on the theory of perfect plasticity. Double Punch Test

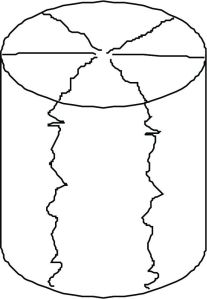

In this test a concrete cylinder is placed vertically between the loading platens of the machine and is compressed by two steel punches placed parallel to the top and bottom end surfaces. Double Punch Test

The sample splits across many vertical diametrical planes radiating from central axis.

Samples should be placed under wet conditions for 24 hours and later on in a curing tank for 28 days.

Calculation

The tensile strength can be computed as; Double Punch Test

where, P = Crushing Load

where, P = Crushing Load

Observations & Calculations:

|

Sr # |

Maximum Applied Load |

Diameter of Specimen |

Length of specimen |

Splitting Tensile Strength |

|

|

Tons |

N |

mm |

mm |

Mpa |

|

|

1 |

12.5 |

122625 |

150 |

150 |

2.97 |

|

2 |

12.75 |

125078 |

150 |

150 |

3.03 |

|

Avg |

12.625 |

123851 |

150 |

150 |

3 |

Comments:

Double punch Test has been performed successfully and the Tensile Strength have been calculated which comes out to b 3MPa as an average value. The dimensions of the Specimens were 150 mm x 150 mm, we have not performed compression test on this sample so we cannot compare our values with those. Usually the Compressive to Tensile Strength ratio is 8 to 15. Taking this concept we can estimate the Compressive Strength of Concrete to vary from 20 MPa to 37.5 MPa. Double Punch Test